Table of Content

- What is ISO 4427-1:2019 PE Piping System Certification?

- Who needs ISO 4427-1:2019 PE Piping System Certification?

- Key Principles of Quality Management in ISO 4427-1:2019 PE Piping System Certification

- Difference Between ISO 4427 and ISO 4437?

- Key Requirements of ISO 4427-1:2019 PE Piping System Certification

- Why Choose ISO 4427-1:2019 PE Piping System Certification?

- Validity Period of ISO 4427-1:2019 PE Piping System Certification

- Process for Obtaining ISO 4427-1:2019 PE Piping System Certification

- The Bottom Line!

What is ISO 4427-1:2019 PE Piping System Certification?

ISO 4427-1:2019 PE Piping System Certification is an international benchmark that specifies general requirements and standards for polyethylene (PE) piping systems used for the water supply of potable water, raw water, and pressurised sewage. It outlines the essential material properties, dimensions, mechanical properties, design requirements, and testing parameters to ensure quality, durability, and high performance of pipelines.

ISO 4427-1 certification reflects that the manufacturer’s piping products are standardised, comply with all regulatory requirements, and meet international safety and quality benchmarks. The certification enhances the product's credibility, ensuring long-term performance.

Who needs ISO 4427-1:2019 PE Piping System Certification?

The following entities benefit from ISO 4427-1:2019 PE Piping System Certification and are required to ensure strict compliance with all the requirements of the certification:

-

PE Pipe Manufacturers

-

Water utilities and municipal suppliers

-

Civil engineering contractors

-

Infrastructure and construction companies

-

Plumbing system suppliers

-

Testing and quality control labs

Key Principles of Quality Management in ISO 4427-1:2019 PE Piping System Certification

The following are the key principles of quality management in ISO 4427-1:2019 certification:

- Material Specification: Ensuring that the compounds conform to classification, performance, and PE requirements as defined in the ISO requirements.

- Process Control and Consistency: Controlling production processes, consistent wall thickness, diameter tolerance, and structural integrity to ensure dimensional accuracy and uniform product quality.

- Testing and Performance: Undergoing regular testing, including hydrostatic pressure tests, strength evaluation, and impact resistance checks. Monitoring performance and striving to improve it.

- Traceability: Developing an effective traceability system to track raw material, production processes, material grade, and batch information to ensure transparency and accountability.

- Continuous Improvement: Analysing data, reports, documentation, customer feedback, and performance reports to ensure continuous improvement and reduce defects in the product.

- Equipment Calibration and Maintenance: Calibrating equipment frequently to ensure accurate results and ensure effective maintenance of the facility and products.

- Documentation and Record Management: Managing and updating documents, including production logs, test reports, calibration records, raw material procurement, and batches of products.

Difference Between ISO 4427 and ISO 4437?

Both ISO 4427 and ISO 4437 sound familiar, but, in reality, they are quite different from each other. ISO 4427 certification covers PE pipes for water supply, while ISO 4437 certification applies to plastic piping systems used for gas distribution. Here’s the key difference between the two:

|

Aspect |

ISO 4427 PE Piping System Certification |

ISO 4437 Plastic Piping System Certification |

|

Application |

PE piping systems for water supply and pressure sewer systems |

Plastic piping systems for gaseous fuel distribution |

|

Material Transported |

Drinking water, raw water, wastewater |

Natural gas and gaseous fuels |

|

Safety Focus |

Water quality and pressure durability |

Gas leakage prevention and pipeline safety |

|

Primary Users |

Water supply utilities and infrastructure projects |

Gas distribution companies and city gas networks |

|

Risk Level |

Moderate risk (water leakage) |

High risk (gas leakage hazards) |

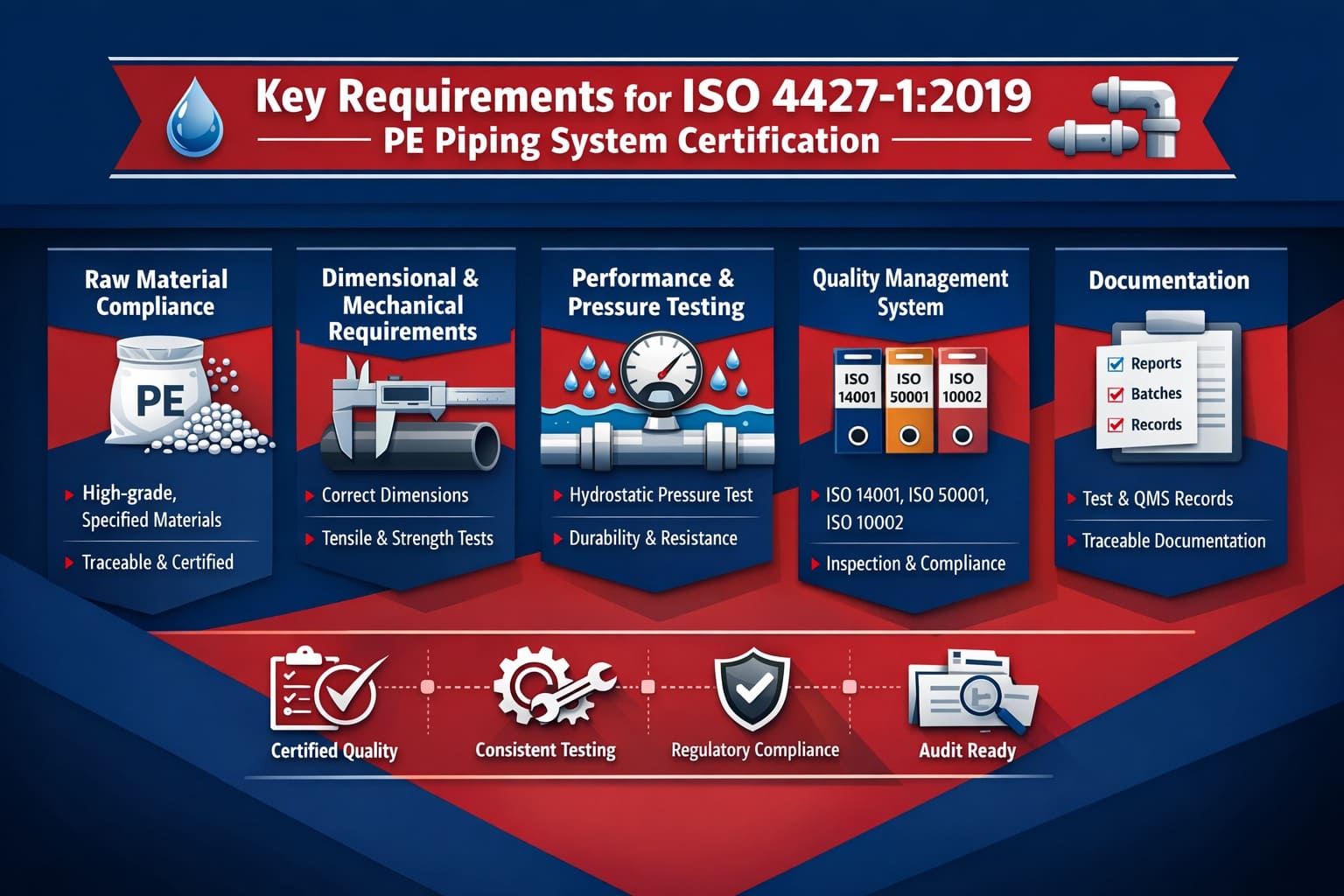

What are the Key Requirements of ISO 4427-1:2019 PE Piping System Certification

Here are the key requirements for ISO 4427-1:2019 PE piping system certification for water supply, drainage, and sewerage under pressure:

1. Raw Material Compliance: The raw material used must meet specific material classification, thickness, tolerance limit criteria, and overall specifications. Only high-quality and traceable raw material should be used to ensure compliance with the requirements of International Organisation for Standardisation.

2. Dimensional and Mechanical Requirements: The PE pipes used for supply should comply with the prescribed outside diameter requirements and structural integrity. Manufacturers are required to check the mechanical properties like tensile strength, elongation at break, and resistance to ensure long-term functionality of the pipes.

3. Performance and Pressure Testing: The manufacturer must undergo hydrostatic pressure testing, internal resistance, and strength testing to ensure that the pipe can withstand high pressure and changing environmental conditions.

4. Quality Management System: The manufacturer must implement a quality management system aligned with ISO 14001, ISO 50001, and ISO 10002. It should cover inspection procedures, testing protocols, non-conformity handling, and corrective actions to ensure continuous compliance.

5. Documentation: The manufacturer must prepare, update, and maintain proper documentation of test reports, QMS reports, material grade, production processes, pressure rating, batch number, and supplier identification. Documentation helps in verification and authentication during internal and external audits.

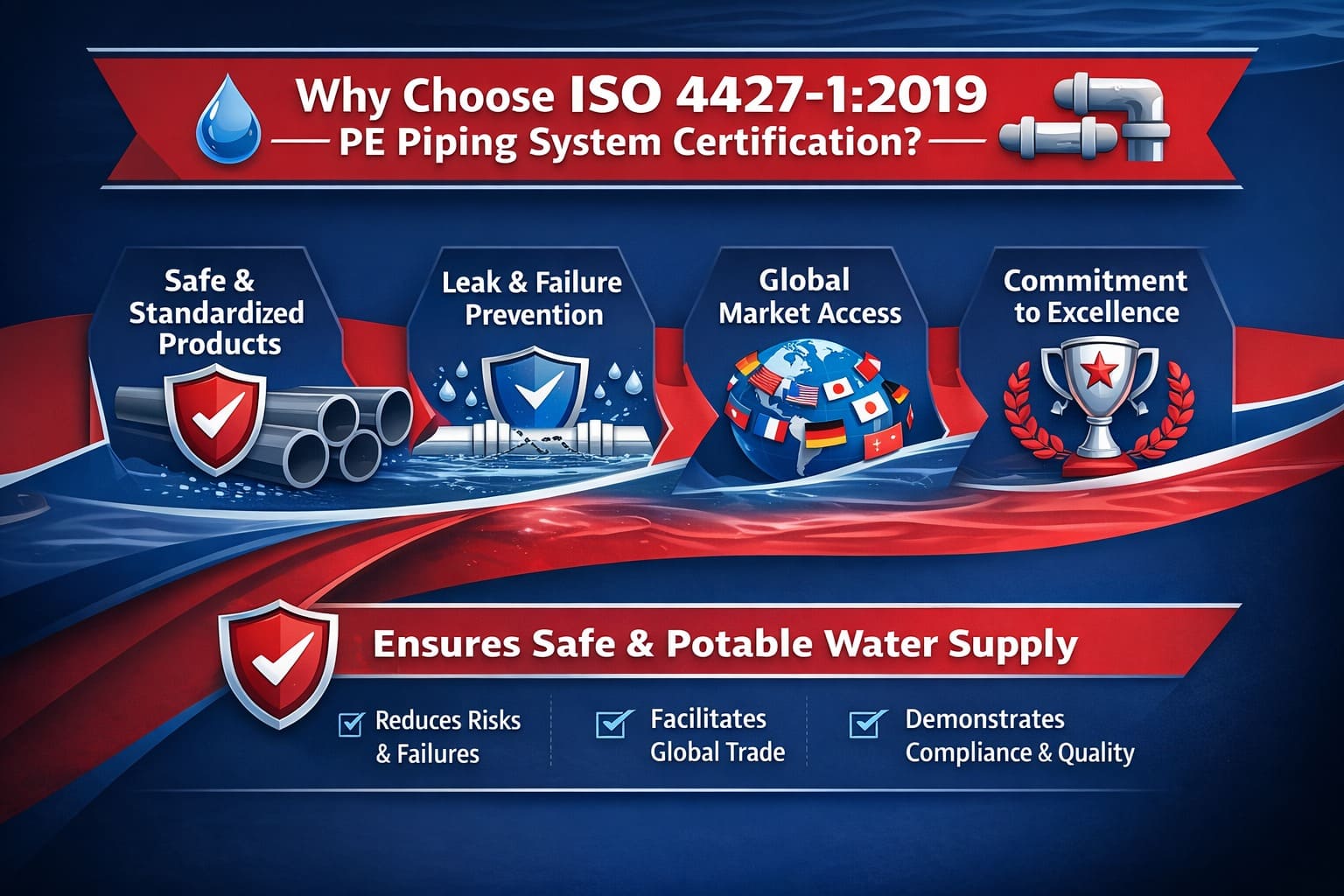

Why Choose ISO 4427-1:2019 PE Piping System Certification?

ISO 4427-1:2019 certification is quite important for manufacturers and suppliers dealing in water supply. It demonstrates that the product is of high quality, durable, safe and conforms to the international standards. It also helps the manufacturers in reducing risks of failure and ensuring a potable water supply. The manufacturer and supplier should choose ISO 4427-1 PE piping system certification because:

1. It demonstrates standardised products, ensuring a safe supply of drinking water.

2. It reduces the risk of leaks, breaks, and premature failures in water supply and pressurised drainage.

3. It facilitates entry into the global market and assists in competing with international brands.

4. It reflects the brand's commitment towards safety, legal compliance, product excellence, and sustainable infrastructure development.

What is the Validity Period of ISO 4427-1:2019 PE Piping System Certification

The validity period of ISO 4427-1:2019 certification is typically 3 years, subject to a successful annual surveillance audit. During this period manufacturers and suppliers are required to maintain compliance with all the certification requirements, including material, testing, quality, durability, and other legal requirements.

After the completion of 3-year period, a re-certification audit is required to renew the certification. The audit is conducted by an accredited certification body. During the audit the manufacturer must demonstrate strong compliance with all the standards. If any non-conformity is found during the audit, the certification body may suspend or cancel the license.

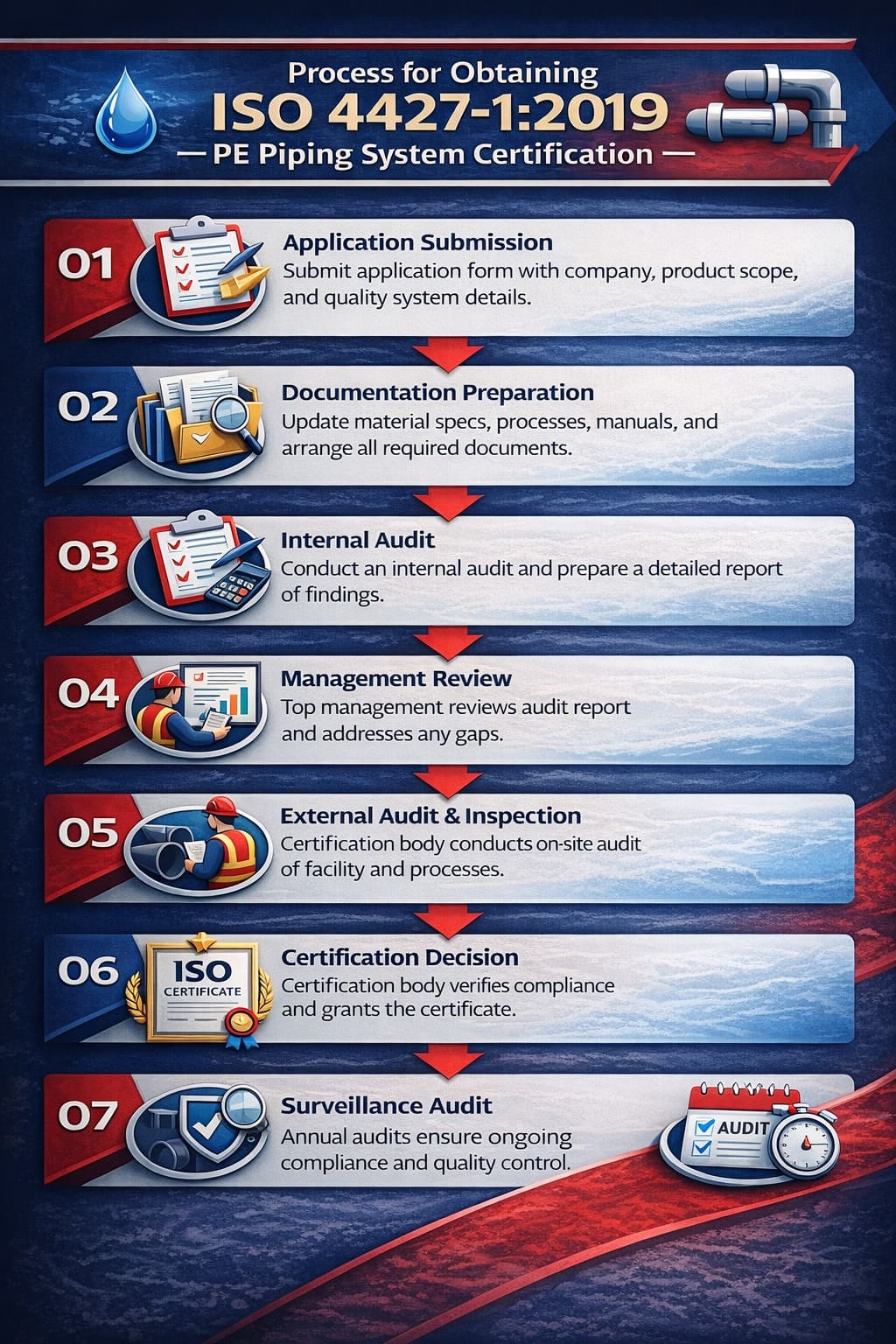

Process for Obtaining ISO 4427-1:2019 PE Piping System Certification

To successfully obtain ISO 4427-1:2019 PE piping system certification, you need to follow these steps:

1. Application Submission

The manufacturer is required to submit an application form to the accredited certification body. The application must include company details, product scope, quality system information, business details, and production details.

2. Documentation Preparation

The next step is to update and arrange all the documents carefully to facilitate the verification and inspection process. The manufacturer must ensure that all the documents, including material specifications, production processes, facility details, quality manuals, test reports, and procedure details, are maintained and updated.

3. Internal Audit

The manufacturer must conduct an internal audit to evaluate the credibility and reliability of the production process, calibration system, inspection methods, traceability practices, and documentation. A detailed report of the audit should be made to facilitate future decision-making.

4. Management Review

The audit report prepared should be reviewed by the top management committee to analyse gaps in the process and to take preventive measures for them. Every process and document should be carefully analysed to ensure compliance and avoid any issues in the certification process.

5. External Audit and On-Site Inspection

The certification body, before taking the certificate decision, visits the facility or conducts an external audit to identify the authenticity of documentation and evaluate the implementation of the certification plan.

6. Certification Decision

After going through everything thoroughly, the certification body, on its satisfaction that every requirement is effectively complied with, grants the certificate.

7. Surveillance Audit

Certification is not a one-time process. The certification body conducts an annual surveillance audit to ensure continuous compliance. The manufacturer is required to monitor the process, production, and records to ensure consistency in quality and legal requirements.

The Bottom Line!

ISO 4427-1 certification ensures reliable, durable, and high-quality plastic piping systems for water supply applications. By complying with this standard, manufacturers demonstrate commitment to performance, safety, and regulatory acceptance. If you face any difficulty while applying for ISO 4427-1 certification, you can contact us to simplify the process and get faster approval.

FAQS

Have some questions about ISO 4427-1:2019 PE Piping System Certification

We have got you covered:

-

Which products fall under ISO 4427-1 Certification?

ISO 4427-1 Certification applies to polyethylene pipes and fittings designed for pressurised potable water distribution infrastructure.

- What materials are covered under ISO 4427-1:2019 PE Piping System Certification?

- What industries use ISO 4427-1 certified piping systems?

- Is ISO 4427-1 certification mandatory everywhere?

- How does ISO 4427-1 certification improve product quality?

- What tests are required for ISO 4427-1 Certification approval?

- Does ISO 4427-1 Certification support exports?

- How long does ISO 4427-1 certification approval take?

- Does ISO 4427-1 Certification require factory inspection?

- Can small manufacturers obtain ISO 4427-1 certification?

- How does ISO 4427-1 Certification benefit customers?

- What performance parameters are evaluated during ISO 4427-1 certification?

- Does ISO 4427-1 certification help regulatory compliance?

- Is product labelling required after ISO 4427-1 certification?

- How does ISO 4427-1 Certification support sustainable infrastructure?

- Does ISO 4427-1 Certification apply to underground piping installations?

- Is batch testing required under ISO 4427-1 Certification?

- Can ISO 4427-1:2019 PE Piping System Certification reduce maintenance costs?

- Can ISO 4427-1 Certification improve product market competitiveness?

- Is training required to maintain ISO 4427-1 certification compliance?